E Class | what is inventory? Can zero inventory be achieved?

Nov 04,2022

Summary

"Do you know what inventory is?" "Inventory? Isn't that what's in the warehouse?"

"Do you know what inventory is?"

"Inventory? Isn't that what's in the warehouse?"

Many friends will come to the above conclusion after hearing the word "inventory". Such a definition can be said to be correct but not comprehensive. You should know that inventory is a very important concept in the production, logistics, retail and recycling process throughout the life of a commodity. In order to better adjust the enterprise strategy, planning business development. Today, we well talk about inventory refers to what?

What is inventory?

The sixth edition of the Modern Chinese Dictionary defines inventory as: existing materials or cash in the library.

The national standard GBT18354 "Logistics Terms" makes a more detailed definition: inventory is used as the goods in idle or non-production state according to the intended purpose in the future. The broad definition of inventory also includes items in the state of manufacturing and transportation.

From these two official definitions, we can see that the characteristics of inventory are: materials that are prepared for future demand, but are not in use for the time being, either have been stored in the warehouse or have not been stored in the warehouse.

What are the pros and cons of inventory?

Having a reasonable inventory is indeed a good thing for business most of the time. Reasonable inventory can play a role in the production and sale of goods to adjust, stabilize, prevent shortages, but also can reduce management costs, shorten the delivery cycle, improve response speed and so on... In short, there is spot, can be delivered immediately mode, for customers always has a strong attraction, just like we always love to ask online shopping "is it spot?"

But are inventories really good for all? To say that there are shortcomings, of course, the most important is "hurt money". Inventory itself will occupy a large amount of funds, warehouse rent, daily maintenance, water and electricity costs are all costs, in addition, if the inventory backlog for a long time, it may lead to the decline of commodity quality, improve the rejection rate.

Can we get rid of the stock?

Can enterprises achieve zero inventory?

The answer is: absolutely!

In the last century, major automobile production factories including Toyota have been taking Ford's "general mobilization" model as a sample. In the face of resource shortage in Japan after the defeat of World War II and the need to occupy a lot of capital and resources for "American production", Vice President of Toyota Daiichi Ohno proposed JIT(Just in time) for the first time in the 1960s.

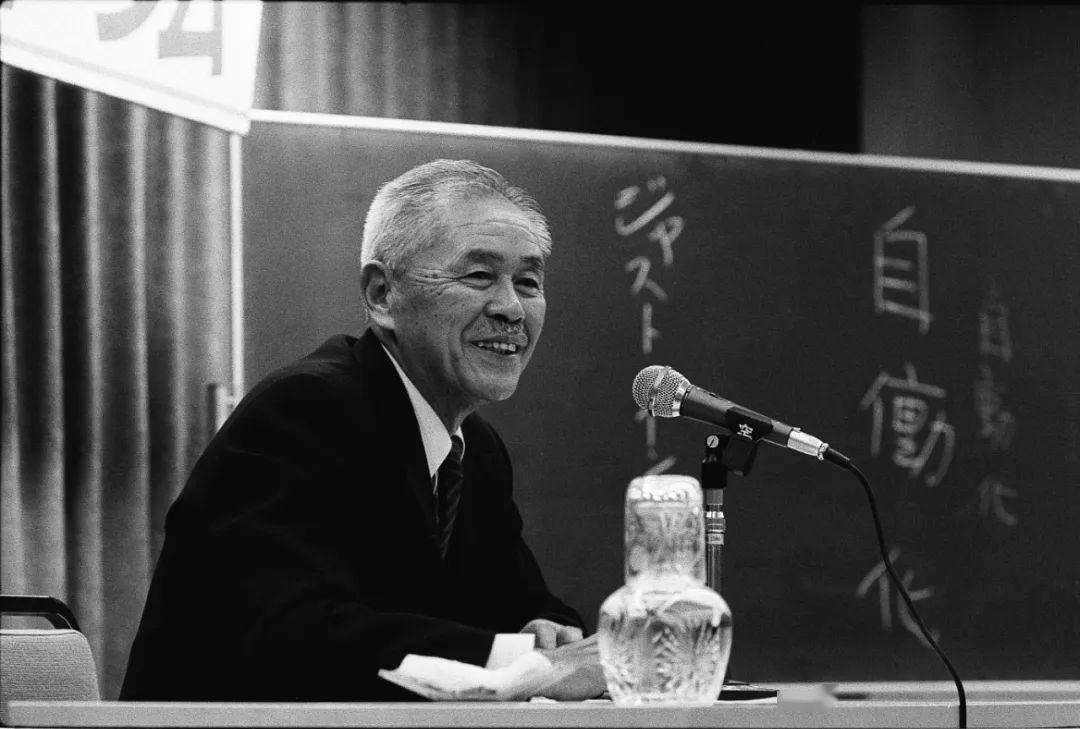

Taiichi Ohno (1912-1990), founder of the famous Toyota method of production

Simply put, it is to send the necessary parts to the production line in the necessary quantity and at the necessary time, emphasize the balance of logistics, in order to continuously eliminate waste, the pursuit of the minimum amount of waste, zero inventory. Raw materials, semi-finished products and finished products in procurement, production, sales and other business links, do not exist in the form of warehouse storage, but are in a state of turnover.

At the same time, JIT also put forward that inventory is a proof of unreasonable design of production system, uncoordinated production process and poor production operation. Zero inventory mode, not only greatly revitalize the working capital, but also reduce the cost of inventory management, to avoid the risk of unsold overstock. After more than half a century, it is still an excellent production mode recognized by all countries in the world.

What about JIT and pulling production? Due to space limited, please continue to pay attention to the "E-Class" column, next time we will explain it for you!

-

Previous:

"Material Flow" interview Andy Jiang, chairman and CEO of Enotek Group -- Intelligent self-research to help China's intelligent manufacturing

-

Next:

Industry Solutions | Enotek Group’s Intelligent Logistics Solution Helps the E-Commerce Retail Industry to Improve the Efficiency of Warehouse Delivery and Realize Operation Automation