E Class | JIT's Development History

Nov 18,2022

Summary

Under the dual impact of the global economic recession and the COVID-19 pandemic, reducing costs and increasing efficiency has become a topic for enterprises to think and explore.

Under the dual impact of the global economic recession and the COVID-19 pandemic, reducing costs and increasing efficiency has become a topic for enterprises to think and explore.

In fact, cost reduction and efficiency improvement is not a new term. As early as in the 1950s after World War II, some people began to actively explore the possibilities of cost reduction and efficiency improvement, and formed a set of effective methodology in long-term practice, which became the benchmark of modern enterprise management and has been passed down to the present day, that is the "JIT".

What is JIT?

JIT is the JIT (Just In Time) production, on Time and real Time production system, by Toyota vice President of ohno put forward In 1953, the birth background, the goal to pursue In the previous E Class | what is inventory? This has already been stated.

Simply put, the concept of JIT is to produce the required products only when needed and in the required quantity. It is a kind of production system that pursues no inventory or minimum inventory. Its core is to avoid all waste by reducing inventory, shortening working hours and improving efficiency.

Its implementation method can be summarized as "interlocking", after the completion of one link of work, immediately into the next link, no waiting, no backlog, no stagnation.

Although the theory sounds simple and easy to understand, but you know, in the manufacturing factory, the production of a product requires as few as dozens of processes, more than hundreds of processes, involving tens of thousands of employees, to complete such a degree of tacit cooperation, if not with the help of some special methods may even be difficult to do.

"Push production" and "pull production"

In the previous "push production", there was often a "separate" situation between the various processes, each process only to do their own work, finished and pushed to the next process, and whether the next process can timely digest these parts, it is not within the scope of consideration, so it is often easy to cause overproduction or insufficient production. Equipment, personnel, raw materials have caused a certain degree of waste.

Taiichi Ohno, the father of Japan's resurrection, on the Toyota production line

In response to the above problems, Ohno went in the opposite direction and innovatively proposed the concept of "pull production", "that is, the starting point of production is not the first process, but the last process. The latter process requires the previous operation to produce exactly needed parts according to the raw materials required for production, and thus moves forward continuously, so as to achieve the requirement of "just right", neither out of supply nor overstocked, skillfully resolving the problem of inventory and waste. "Pull production" is also the technical payload for JIT implementation.

JIT's magic weapon: spectaculars

"Pull production" sounds as smooth as water, but there is a prerequisite for its implementation and operation: requirements must be clearly communicated between each department and process. Unclear requirements and unclear instructions will clog up the entire assembly line. To this end, Ohno uses a seemingly simple but perfect solution: spectaculars!

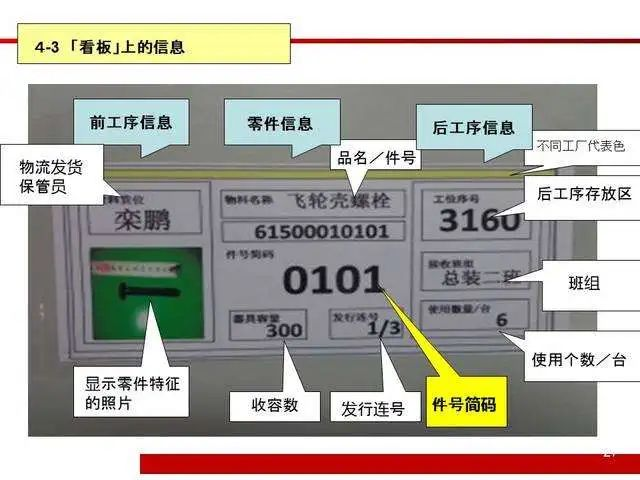

"Toyota-style" spectaculars

All production orders are transmitted upward through spectaculars, which also specifies: No spectaculars can not be produced or transported, spectaculars can only come from the post-process, the pre-process can only produce the parts taken, the pre-process according to the order of receiving spectaculars production, spectaculars must be together with the physical, do not give defective products to the post-process and other rules of use, strict implementation of the system, to ensure that JIT will not fall into formalism.

With the development of The Times, spectaculars has been replaced by information and digitalization. Many enterprises have introduced MRP system to transmit instructions and information more efficiently, but its essence and kernel are always JIT production created by Taiichi Ohno.