Industry Solutions | Enotek Group’s Intelligent Logistics Solution Helps the Household and Kitchen Appliances Enterprises Reduce Costs and Increase Production Capacity

Nov 28,2022

Summary

The client of this case is China's well-known kitchen cooker and appliance leading enterprise, which main business is intelligent cookers, smart home appliances and kitchen appliances. With its excellent R&D strength and manufacturing capacity, it has been recognized by many well-known enterprises in the world. Its products are exported to more than 40 countries and regions such as the United States, Germany and Australia all the year round, and it has also been rated as recommended export enterprises by the China Chamber of Commerce for Import and Export of Mechanical and Electrical Products. In 2021, the annual operating revenue has reached 3.008 billi

The client of this case is China's well-known kitchen cooker and appliance leading enterprise, which main business is intelligent cookers, smart home appliances and kitchen appliances. With its excellent R&D strength and manufacturing capacity, it has been recognized by many well-known enterprises in the world. Its products are exported to more than 40 countries and regions such as the United States, Germany and Australia all the year round, and it has also been rated as recommended export enterprises by the China Chamber of Commerce for Import and Export of Mechanical and Electrical Products. In 2021, the annual operating revenue has reached 3.008 billion yuan and the export amount is about 1.8 billion yuan.

The reason for keeping the export volume at a high level depends on the high efficiency and standardization of the production system in addition to the excellent product quality. For this reason, the enterprise has invested in the construction of a new factory in the east of Wenling, covering an area of 430,000 square meters, and the total cost of the project is 1 billion yuan.

Enotek has created a full-link intelligent logistics solution integrating intelligent hardware and software according to the actual production demand and factory operation process, which has effectively improved production capacity and yield, shortened the product upgrade cycle, and reduced labor costs and energy consumption. With the intelligent logistics and warehousing system, it helps the company's logistics turnover efficiency improved, empowers the high-quality development of "intelligent manufacturing" and achieves cost reduction and efficiency increase.

PROJECT KEY POINTS

1. Traditional production, storage and handling require a lot of labor with low per capita unit operation efficiency.

2. The original production workshops and warehouses are scattered, and the degree of intensification is low.

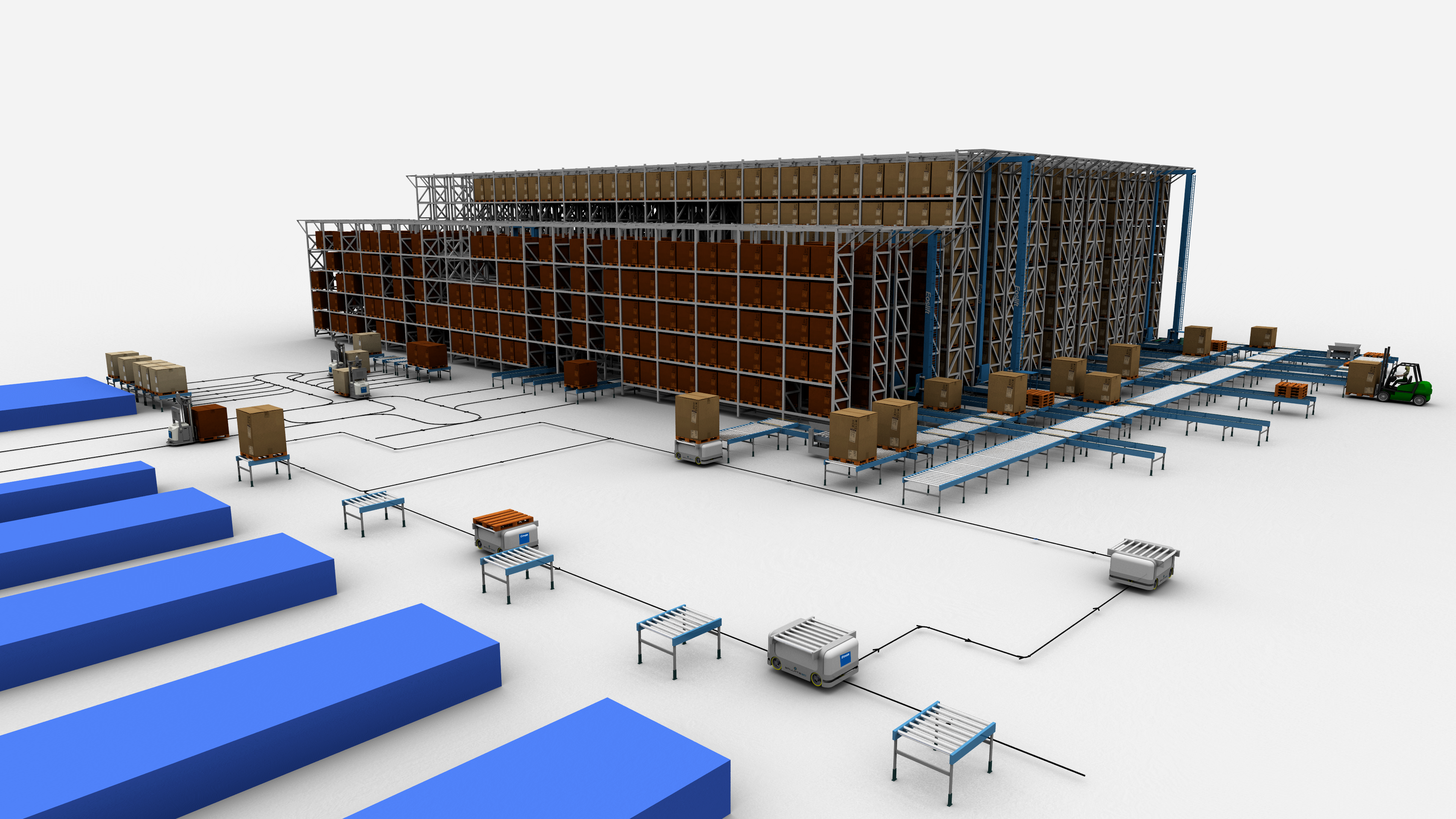

SYSTEM EQUIPMENT

Enotek provides clients with a full-link logistics solution from intelligent hardware to software, and achieves the automatic process of production line changeover and mold changeover.

1. 17 stackers.

2. 25 Automated Guided Vehicles.

3. 1 set of AGV dispatching system.

PROJECT DETAILS

1. Intelligent Warehousing System

The system consists of a stacker, a conveying system and a control and software system. This solution has the function of inventory product lookup, which can achieve automated, uninterrupted inspections of expired products.

2. AGV Automated Material Handling Solutions

Enotek has deeply integrated the AGV equipment with the factory production process, achieving various short and long-distance handling works such as receiving goods, entering and exiting warehouse, transporting and handling, which greatly reduces the intensity of manual labor.

3. Automatic Mold Change Solution

Fulfill the automatic mold change function of the production line, take out the mold from the exit of automatic storage/retrieval system by conveyor and transport it to the designated mold changing position, replace the old mold with a new one, and then transport the old mold back to the automatic storage/retrieval system for storage.

PROJECT ACHIEVEMENTS

1. Increased efficiency and reduced cost

The production efficiency is increased by 22.46% on average;

The operating cost decreased by 23.16% on average;

Labor costs reduced by 60%.

2. Increased production capacity and reduced inventory

The annual production capacity increased by 2.5 times to more than 36 million sets;

The product upgrade cycle was shortened by 34.8%;

Inventory decreased by 70%.

3. Reduced energy consumption and defective products

The defective rate of products decreased by 30.5% on average;

Energy consumption per unit output value decreased by 21.1% on average.