E class | Do you still can’t clarify what WMS and WCS are?

Dec 11,2022

Summary

When you hear WMS/WCS, you often ask, what's the difference? What’s the connections?

When you hear WMS/WCS, you often ask, what's the difference? What’s the connections?

To explain this problem, we must first sort out the three levels of automatic storage system. The upper level of the storage system is the WMS warehouse management system, which is responsible for the processing of storage business logic; WCS warehouse control system is located in the middle layer, responsible for dispatching various logistics equipment at the bottom; At the bottom level are specific logistics equipment, such as stackers, AGV/RGV systems, etc.

WMS is short for Warehouse Management System. The national standard GB/T 18354-2021 logistics terms explain WMS as follows: A computer information system for the overall management of goods warehousing, warehousing, inventory and other related warehouse operations, storage facilities and equipment, storage locations, etc.

Generally speaking, WMS is like the central nervous system of the brain. It can analyze and judge the situation of spare storage space and SKU heat in the warehouse in real time, and plan, organize, guide and control all kinds of resources in the warehouse based on this, and manage the storage and movement of goods (in-storage, out-storage and in-storage movement) in combination with big data algorithm. It is an important system to improve storage efficiency, storage security and stability.

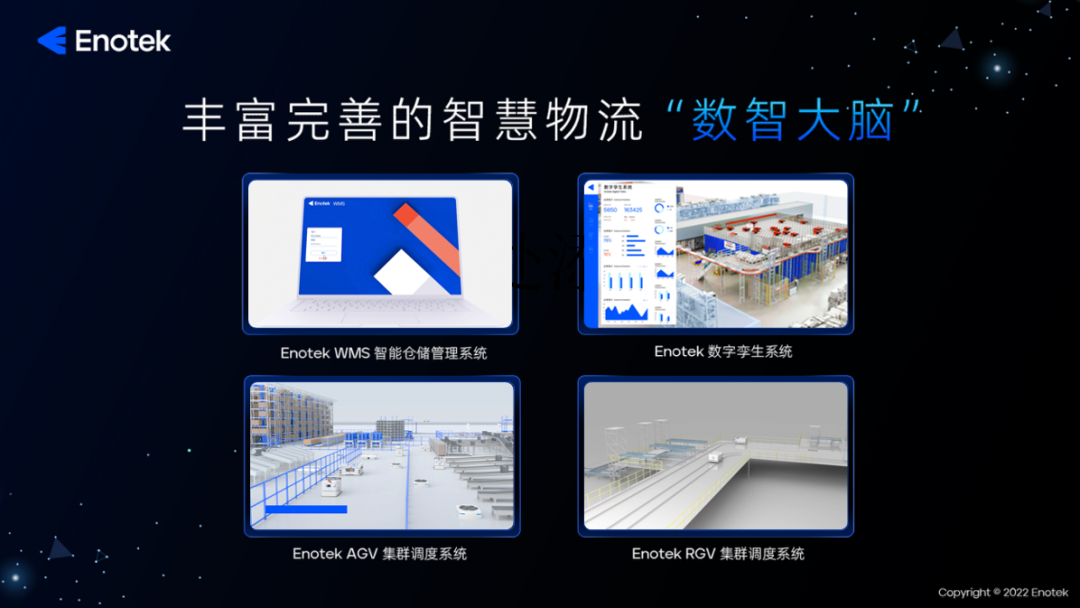

And the new generation of WMS can often achieve more functions, to a technology Enotek self-developed and self-produced WMS example, in addition to the basic functions, but also set report management, print management, basic management, document management, docking management, delivery management, strategy management and other eleven functions in one, It also has AI autonomous learning ability, disaster recovery ability and digital twin visualization ability.

With the central nervous system (WMS), the specific logistics equipment control is handed over to the WCS to handle. WCS is a layer of management control system between the WMS system and the PLC system, which can coordinate the operation of various logistics equipment, such as conveyor, palletizer, shuttle car, robot, guide car and other logistics equipment. The main realization of various equipment system interface integration, unified scheduling and monitoring.

Generally, WCS have automatic access, sorting and packaging; Automatic control and management of production lines; Implement monitoring of production line dynamics; Automatic allocation and execution of WMS warehouse management software production tasks and other functions, that is, WCS is a system with a link to work. Of course, in some applications with few devices and single scenarios, such AS Mini-Load AS/RS, small devices can also be directly controlled and managed by WCS.

1.WMS mainly serves for business management and report data presentation. It calculates all kinds of data through certain data algorithms and obtains various outputs.

2.WCS is more about on-site equipment and materials, and has little interaction with the business level.

3.WMS is mainly responsible for displaying and calculating results, while WCS is mainly responsible for delivering results and uploading data.

4.WMS is the upper level system of WCS, as shown in the diagram below:

When it comes to smart logistics, you may often hear about supply chain, orders,

AS/RS, AGV... So, what do they mean? Please continue to pay attention to "E Class" column, we will explain more industry knowledge for you!