3C

This enterprise is a large manufacturer for 3C product, the planning engineer of Enotek has planned and designed the whole production and packaging logistics process, including advanced automated logistics technologies such as intelligent warehouse for goods to people, robot picking, smart conveying and picking, PPS automated packaging line, etc. Among them, AGV plays a key role between automatic warehouse and production workshop, between stations and between sections of conveying lines.

Project Location

Kunshan

Launch Time

2020

Type Of End User

Provide earphones for some well-known phone brand

Key Points Of Project

-

01

Customized goods, >2,000 SKUs

-

02

How to improve labor efficiency and reduce costs when a great number of labors are required for picking.

-

03

How to guarantee picking accuracy and improve the picking efficiency

-

04

How to realize traceability throughout the whole process

System Equipment

-

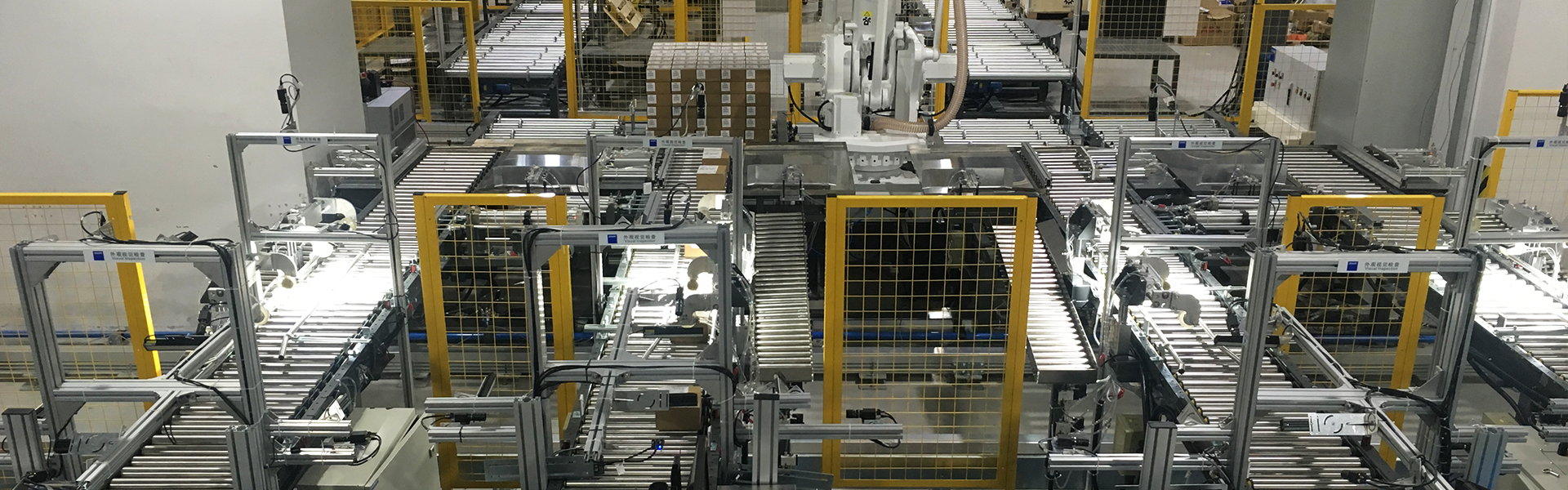

It includes advanced automated logistics technologies, such as GTP intelligent warehouse, robotic picking, intelligent transportation & sorting and PPS automated packing line.

-

Robot: 3 sets of 6-axis picking robots and 2 sets of 4-axis robot stackers.

-

AGV:16 sets of KAVA, 2 sets of forklift laser SLAM

-

PPS automated line: Made up of automatic sorting line, automatic labeling machine, automatic visual inspection mechanism, etc.

-

Software: One set of WMS and WCS system

Project Outcome

Labor cost is reduced by 80%.

Production line only needs a few workers, with the rest station realized automatic equipment operation.

Labor costs are reduced by about CNY 6 million per year.

Help clients create ultimately efficient supply chain system with intelligent product,systematic solution, continuously maximizing commercial value