INTEK album | Chat about digital twin technology in the development of logistics industry

Feb 24,2022

Summary

Digital Twin: Digital Twin enables the physical world and the information world to realize virtual-real mapping and two-way interaction, and plays a great role in the construction of smart cities and smart factories. In November 2020, the Ministry of Industry and Information Technology defined the basic concept of digital twinning at the national level.

Digital Twin: Digital Twin enables the physical world and the information world to realize virtual-real mapping and two-way interaction, and plays a great role in the construction of smart cities and smart factories. In November 2020, the Ministry of Industry and Information Technology defined the basic concept of digital twinning at the national level.

In the logistics industry, digital twin technology also plays an important role. By virtualizing logistics equipment in the real world, we can rely on big data and machine learning to analyze massive logistics data, optimize storage structure of warehouses, optimize operation efficiency of equipment, and assist decision-making and maintenance, thus unleashing great potential for enterprises.

Before digital twin technology officially became a hot topic in logistics equipment field, equipment monitoring has been widely known in logistics industry.

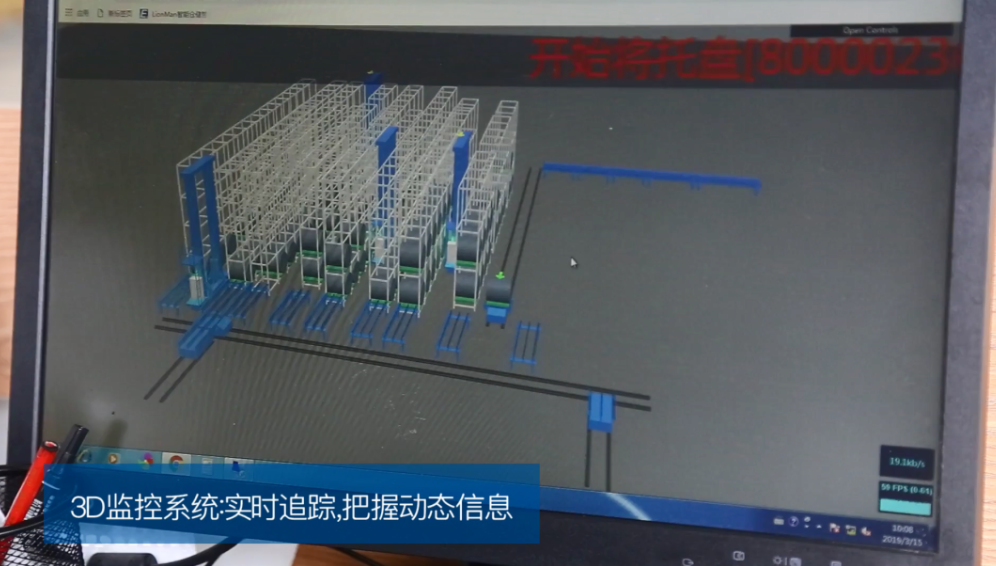

In 2018, in the intelligent logistics project implemented by Enotek Group for Zhejiang Dingmei Smart Equipment Co., LTD., Enotek Group equipment monitoring innovation adopts 3D mode with better experience, to realize equipment monitoring in the reservoir area for customers. This technology allows customers to check the equipment information at any time, understand the working situation of the reservoir area, monitor the equipment operation information, and find the equipment failure in time.

At the time, however, 3D monitoring technology was crude. Although the 3D three-dimensional monitoring in the reservoir area has been realized, it is not precise enough in the scene and equipment display. The tiny movements of many devices cannot be displayed, and the massive data cannot be processed.

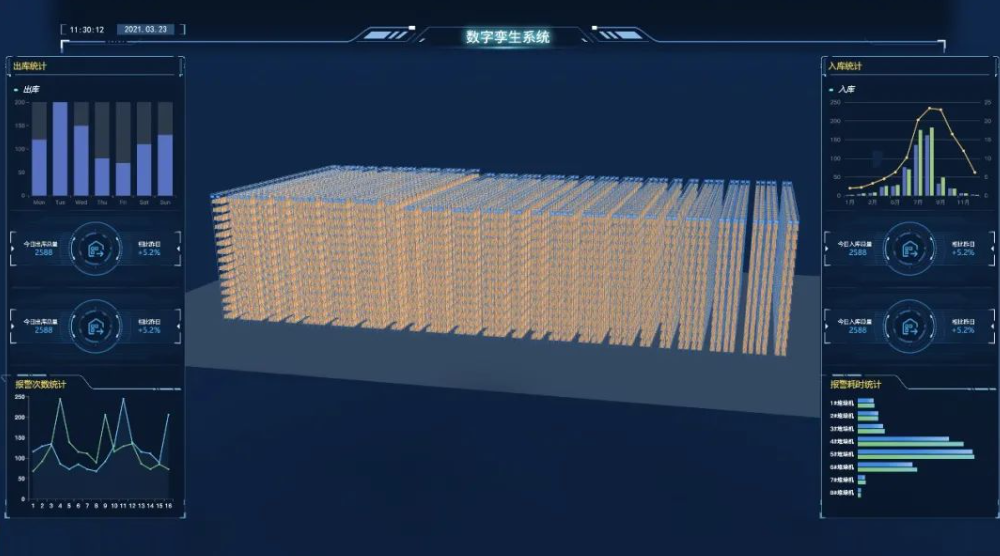

With the further development of hardware and software technologies such as 5G communication and virtual simulation, 3D monitoring technology has gradually developed into a technology with a more scientific name -- digital twin. Enotek Group's 3D monitoring system is also iteratively upgraded to Enotek Group digital twin system after the implementation and application of multiple projects. In 2020, Enotek Group deployed its first digital twin system for a customer in the glass fiber industry, realizing 3D visual display of equipment and cargo locations in the storage area, real-time and accurate reflection of their working status, providing accurate reports for managers to make decisions.

Of course, from 3D monitoring to digital twinning, the upgrade is more than just name calling. Enotek Group Digital Twin offers the following upgrades over previous 3D monitoring systems:

The display interface is fully updated and the operation is more friendly

Higher degree of visualization, finer granularity, higher degree of twinning, equipment status and cargo location information clearly visible

Realize multi-scene and multi-region display, multi-region smooth transformation,

Achieve data connection with WMS/WCS system and AGV dispatching system, and view AGV device running report in real time

More intelligent devices and sensing devices can be connected to display more data, such as temperature and humidity

More diversified customized reports and configurable functional modules enable rapid deployment

On October 8, 2021, a glass fiber industry customer of Enotek Group laid the foundation stone of a glass fiber tank kiln drawing production line with an annual output of 120,000 tons in Egypt. Enotek Group will build an automated stereo library and intelligent production line for it. This is Enotek Group's first African project so far, and the updated version of the digital twin system will also play an important role in the project.

E management

Enotek Group's new version of digital twin technology can provide more refined and visual data, create the whole process of visual management, better help customers to do production process optimization and decision aid:

Have a deep understanding of the mechanism of the equipment: started from the equipment manufacturing and have the ability of self-research, more familiar with the operation logic of the equipment. Compared with simply accessing third-party data to do digital twinning, richer and deeper device data types and data contents can be obtained.

Rich industrial experience: in-depth understanding of Chinese manufacturing process and demand pain points.

Equipped with intelligent maintenance system: it can detect the condition of hardware equipment and provide early warning.

Data refinement: Due to the advantages of independent research and development of Enotek Group technology products, Enotek Group provides richer device data access for Enotek Group digital twin system, which can realize more accurate and non-delay visual presentation.

Data analysis ability: can assist customers to make decisions, effectively realize the optimization of warehouse structure.

As a new infrastructure of intellectual collaboration, digital twinning will effectively solve the contradictions between education and training, integration and design, operation subjects and equipment research and development in the logistics industry. In this way, enterprises can effectively manage individual businesses to better cope with the impact of diversified, personalized and customized demands. Through intelligent logistics management and intelligent logistics system, we can open up the common wisdom of man and machine, and the common wisdom of intelligent bodies, and ultimately reduce the cost of resource adaptation between logistics network and supply chain. At the same time, from the demand side, to accelerate the 5G/AI/ cloud computing and other technologies real value landing.