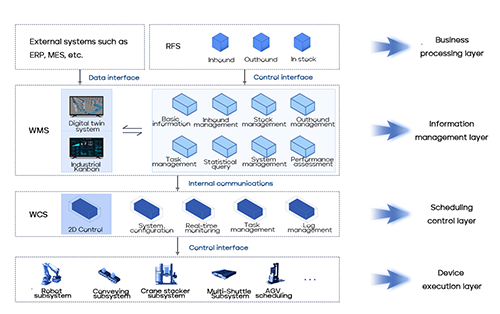

The WMS and WCS system independently developed by Enotek has powerful inventory management functions. It can be used together with various intelligent warehousing equipment to perform efficient inbound and outbound count. Thanks to strong secondary development capability, our system can adapt to various complicated warehouse management processes and match all upper systems for customized development. When this system is used together with AI, machine learning and big data analysis, it can obtain the best location of goods, maximize the inbound and outbound efficiency. Big data analysis is applied to count the frequency of use of goods and inventory retention, providing the best inventory structure report to the management. In this way, inventory management can be reinforced and inventory costs can be effectively saved through taking corresponding measures to reduce inventory.

Advantages

-

Excellent software framework

Quickly adapt to changing customer needs; and support multiple terminals operation (PC, mobile phone, etc.)

-

A variety of software interfaces

Able to respond to different upper systems to ensure rapid docking development (DBLink, webservice, etc.)

-

AI big data algorithm

Learning client’s outbound and inbound efficiency access path KPI in a systematic manner to analyze the optimal path; big data algorithm is adopted to analyze the optimal location to maximize the inbound and outbound efficiency.

-

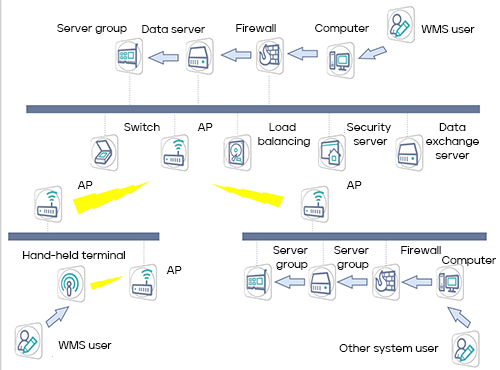

Matured communication protocol

This protocol abandons traditional OPC communication mode, making communication faster and more flexible; Enotek’s powerful software and electrical team has verified the custom communication protocol through multiple projects to ensure stable and reliable communication.

Communication Process

It abandons traditional OPC communication mode, making communication faster and more flexible;

Enotek’s powerful software and electrical team has verified the custom communication protocol through multiple projects to ensure stable and reliable communication.

Help clients create ultimately efficient supply chain system with intelligent product,systematic solution, continuously maximizing commercial value