Product recommendation | The exploration and application of Enotek Group digital twin technology in the field of intelligent logistics

Jul 21,2022

Summary

Digital Twin is also known as digital mapping and digital mirroring. Digital twinning is a multi-disciplinary, multi-physical quantity, multi-scale and multi-probability simulation process that makes full use of physical model, sensor update, operation history and other data, and completes mapping in virtual space, so as to reflect the full life cycle management of corresponding physical equipment.

About digital twin

Digital Twin is also known as digital mapping and digital mirroring. Digital twinning is a multi-disciplinary, multi-physical quantity, multi-scale and multi-probability simulation process that makes full use of physical model, sensor update, operation history and other data, and completes mapping in virtual space, so as to reflect the full life cycle management of corresponding physical equipment.

The application of digital twin in the field of intelligent logistics

In industrial intelligent logistics industry, digital twin technology also plays an important role. By virtualizing logistics equipment in the real world, we can rely on big data and machine learning to analyze massive logistics data, optimize storage structure of warehouses, optimize operation efficiency of equipment, and assist decision-making and maintenance, thus unleashing great potential for enterprises. As a full-link industrial intelligent logistics solution provider with the best cost performance, the digital twin system of its core product can realize big data analysis, three-dimensional visualization, real-time visibility, and dynamic display of the whole process. Let's share the exploration and application of digital twin technology of Enotek Group in the field of intelligent logistics.

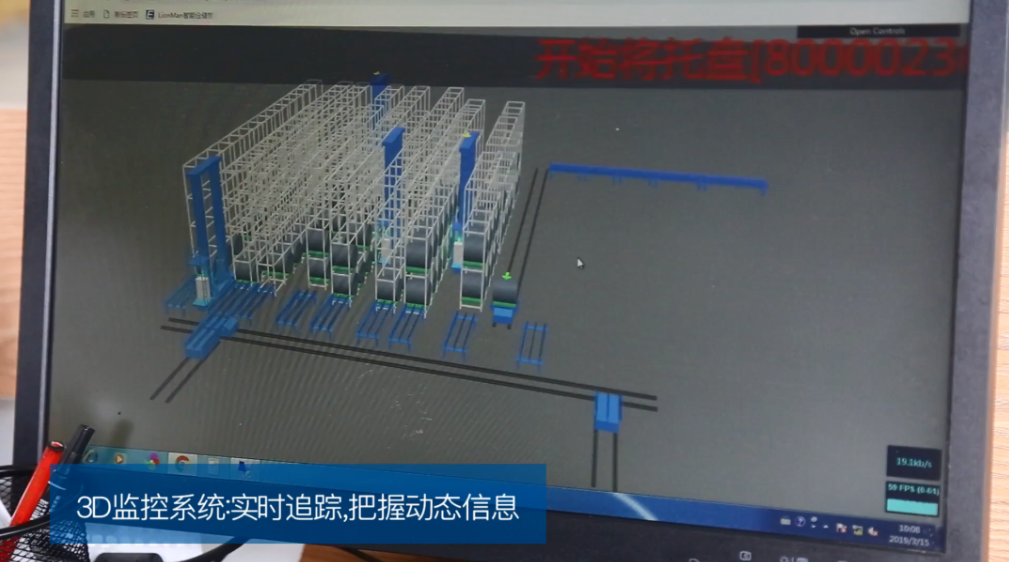

In 2018, in the intelligent logistics project of Zhejiang Dingmei Smart Equipment Co., LTD., Enotek Group 's equipment monitoring innovation adopted 3D mode, which realized the equipment monitoring in the reservoir area for customers. Help enterprises to check equipment information at any time, understand the working situation of the reservoir area, monitor the running status of the equipment, and discover equipment faults in time.

At first, 3D monitoring technology was crude. Although the 3D three-dimensional monitoring in the reservoir area has been realized, it is not precise enough in the scene and equipment display. The tiny movements of many devices cannot be displayed, and the massive data cannot be processed.

With the further development of hardware and software technologies such as 5G communication and virtual simulation, 3D monitoring technology has gradually developed into a technology with a more scientific name -- digital twin. Enotek Group 's 3D monitoring system is also iteratively upgraded to Enotek digital twin system after the implementation and application of multiple projects.

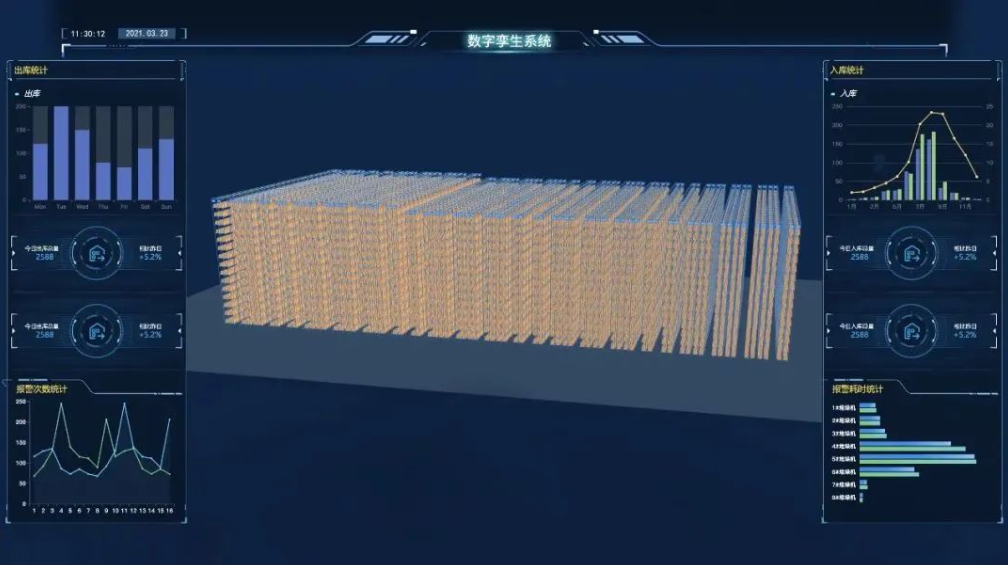

In 2020, the company deployed its first digital twin system for a customer in the glass fiber industry, which can visually display the equipment and cargo locations in the reservoir area in three dimensions, reflect the working status in real time and accurately, provide accurate reports, and provide decision-making basis for managers.

From 3D monitoring to digital twinning, Enotek Group system has achieved the following upgrades:

1. The display interface is updated comprehensively and the operation is more friendly

2. Higher degree of visualization, finer granularity, higher degree of twinning, equipment status and cargo location information clearly visible

3. Multi-scene and multi-region display, multi-region smooth transformation,

4. Make data connection with WMS/WCS system and AGV dispatching system, and view AGV device operation report in real time

5. Access of more intelligent devices and sensing devices can realize more data display, such as temperature and humidity

6. More diversified customized reports with configurable function modules can realize rapid deployment

On October 8, 2021, a glass fiber industry customer officially laid the foundation for a glass fiber pool kiln drawing production line with an annual output of 120,000 tons in Egypt. Enotek Group Technology will build an automated stereo library and intelligent production line for it, and will play an important role in the application project of the new version of digital twin system after iterative upgrading.

Enotek's new version of digital twin technology can provide more refined and visual data, create the whole process of visual management, better help customers to do production process optimization and decision aid:

Have a deep understanding of the mechanism of the equipment: started from the equipment manufacturing and have the ability of self-research, more familiar with the operation logic of the equipment. Compared with simply accessing third-party data to do digital twinning, richer and deeper device data types and data contents can be obtained.

Rich industrial experience: in-depth understanding of Chinese manufacturing process and demand pain points.

Equipped with intelligent maintenance system: it can detect the condition of hardware equipment and provide early warning.

Data refinement: Enotek Group provides richer device data access for digital twin systems due to its self-developed products, enabling more accurate and time-free visualization.

Data analysis ability: can assist customers to make decisions, effectively realize the optimization of warehouse structure.