Enotek Group 2022 Review -- Case Study

Dec 21,2022

Summary

2022 will be the first year that Enotek Group officially completes its brand upgrade. During the year, Enotek Group deployed new strategic plans, won new honorary awards, developed new core hardware and software products, and made great progress in planning, business, product and other aspects. In the year-end review series, we will look back with you at this year of striving, carrying on the past and opening up, and look forward to the next year with infinite possibilities!

2022 will be the first year that Enotek Group officially completes its brand upgrade. During the year, Enotek Group deployed new strategic plans, won new honorary awards, developed new core hardware and software products, and made great progress in planning, business, product and other aspects. In the year-end review series, we will look back with you at this year of striving, carrying on the past and opening up, and look forward to the next year with infinite possibilities!

Enotek Group, as an "innovation-driven full chain industrial intelligent logistics solution provider", not only realize the production of hardware standards such as AGV, RGV, stacker, but also the software development of digital intelligent brain systems such as WMS/WCS, AGV/RGV dispatching system, digital twin. It also has a strong industrial design team, project implementation team and after-sales service team. With excellent innovation, service and delivery, it tailors exclusive integration solutions for the upgrading and transformation of the manufacturing industry under the background of "thousands of factories and thousands of faces". It combines self-developed core hardware and software with lean industrial design, and applies the principle of water storage and caching and flow balance design to logistics warehousing. To bring customers reliable, efficient, stable, the ultimate logistics experience.

Among them, the full-link integrated intelligent logistics solution provider for a leading enterprise in the chemical fiber industry won the 2022 Golden Globe Award -- the Annual Benchmark Case Award of intelligent logistics Solution for enterprises in the chemical fiber industry; The cargo to person intelligent logistics system created for the e-commerce retail industry won the "Logistics Academy Award" LT Innovative Application Award.

So what are the pain points in each industry? What kind of solution does Enotek Group offer? This article will tell you!

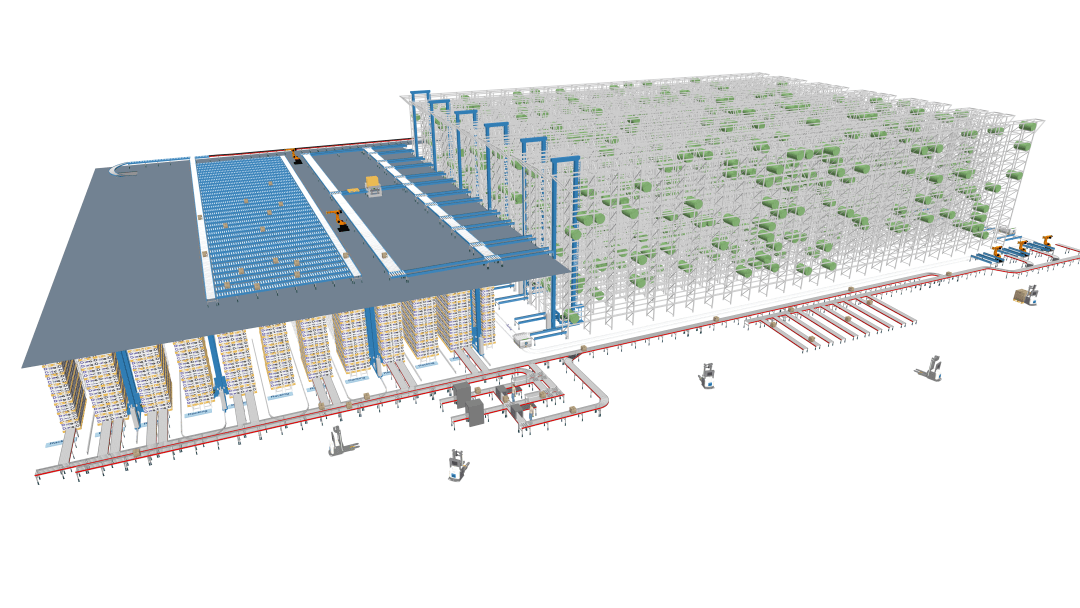

Enotek Group instead of the previous flat warehouse storage, manual handling, the establishment of automatic three-dimensional warehouse, greatly improving the storage of goods; And through the WMS and WCS system independently developed by Enotek Group, fully automated warehousing and goods inventory. The completion and production of the project further optimized the product structure of the enterprise, improved the added value of the product, and effectively improved the core competitiveness and market share of the enterprise. This case was awarded the Golden Globe Award of the year Benchmarking case.

Based on client needs and industry experience, Enotek Group has designed a full-link industrial intelligent logistics solution for clients, and provides one-stop services from project design to implementation. The brand-new glass fiber warehouse has a total height of 30 meters, a floor height of 15 floors, 18 double-deep lanes, and 51,720 cargo spaces in total.

The full-link intelligent logistics solution provided by Enotek Group for a well-known large new energy lithium battery provider in China has realized: the lithium battery can be storage in the high temperature warehouse of 50 degrees Celsius with the stacker which can resist high temperature; polyurethane coated rubber wheel and H-section steel/aluminum alloy stacker track meet the environmental cleanliness requirements of lithium battery production, such as dust and burr free; stacker equipped with fire extinguisher and armor device to meet the requirements of fire and explosion; the WMS/WCS system can achieve the whole process automatically and unmanned, and record product information throughout the process to realize the information can be traced at any time, helping to improve the consistency of battery products.

Enotek Group has created a full-link intelligent logistics solution integrating intelligent hardware and software according to the actual production demand and factory operation process, which has effectively improved production capacity and yield, shortened the product upgrade cycle, and reduced labor costs and energy consumption. With the intelligent logistics and warehousing system, it helps the company's logistics turnover efficiency improved, empowers the high-quality development of "intelligent manufacturing" and achieves cost reduction and efficiency increase.

After deeply understanding the actual site and business requirements of clients, Enotek Group creatively brought the design thinking of industrial pull system into the TOB/TOC business of new retail e-commerce, combining the principle of water storage with the design of flow balance, and efficiently implementing intelligent hardware such as annular MINI LOAD, AMR, goods-to-people workstation, light-picking and replenishment of displaced shelves, transportation and sorting system, etc., which achieved the collection, putting, order fulfillment and goods-to-people under wave conditions. The design concept of "small but beautiful, small but fine" has won the LT Innovation Application Award.

The intelligent storage case provided by Enotek Group for the pharmaceutical industry has realized the highly intelligent operations from receiving goods to order delivery, greatly reducing the pressure of manual work, compared with traditional warehouses, it achieves highly automated and greatly saving staffing with a total of more than 20 operators, and increasing the efficiency of warehouse entry and exit by 2-3 times. Achieve the high-density storage of goods, ensure the maximum utilization of warehouse space, and increase the storage capacity of the warehouse by 4-5 times compared with the original warehouse.

The entire warehouse operation process can be monitored in real time through the WMS software. The perfect information management system alleviates the warehouse management pressure of goods, reduces errors caused by human factors, and meets the relevant management requirements of first in, first out by batch number for drug circulation.

Relying on precise products, lean design, dedicated spirit and decades of deep industry technology accumulation, Enotek Group has so far provided services for Tongkun Group, China Jushi, SINOTRUK, Gotion High-Tech Co.,Ltd, BYD, and other global enterprises, helping customers to land more than 100 smart logistics projects. In 2023, Enotek Group will have more new cases completed and put into use, please continue to pay attention to us!