New Energy

A leading power battery enterprise in East China uses a large number of automation systems in transportation, picking, packaging and storage in its charge and discharge test and process flow. In this project, Enotek provided a comprehensive solution that includes technologies and services ranging from stand-alone equipment to warehousing and logistics management system.

Project Location:

Kunshan

Launch Time:

2020

Type Of End User:

A well-known large new energy lithium battery supplier in China

Key Points Of Project

-

01

High-temperature warehouse with temperature up to 50°+-5°; formation/grading warehouse at ordinary temperature 45+-3℃.

-

02

The temperature (24+-3℃), relative humidity (dew point of anode and cathode workshop≤ -4), cleanliness (anode and cathode workshop≤100,000) .

-

03

Lithium batteries set higher requirements on handling, load, lamination and directionality.

System Equipment

-

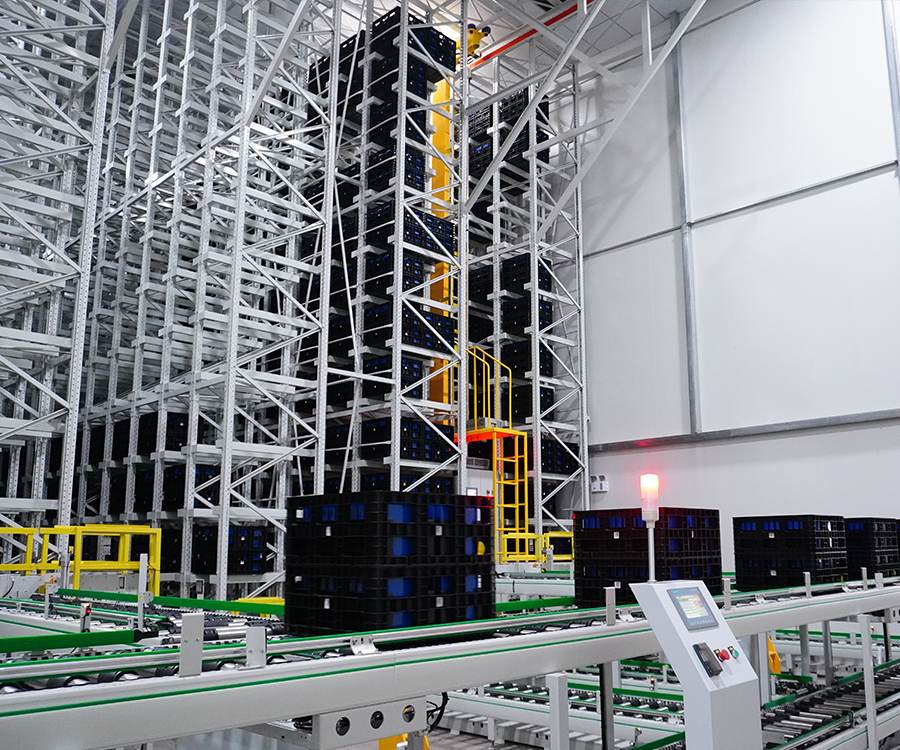

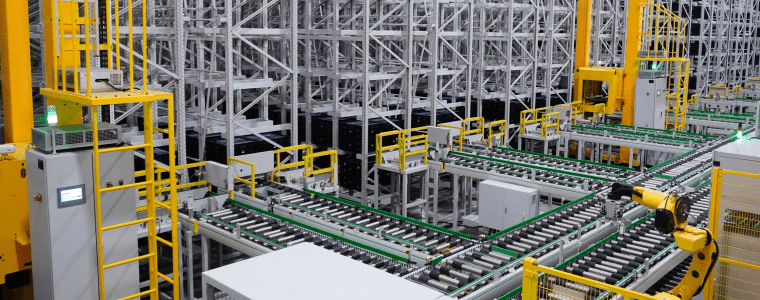

50℃ high-temperature warehouse adopts four stackers to complete the storage & retrieval of lithium batteries after being dried. It provides 4,160 pallet locations.

-

Formation warehouse consists of three stackers, used to complete the storage & retrieval of lithium batteries filled with electrolytes;

-

Grading warehouse utilizes three stackers to complete the capacity grading, storage & retrieval of lithium batteries.

-

Normal temperature standing warehouse utilizes four stackers to complete storage & retrieval of lithium batteries that need standing and to be stored temporarily. 21,024 pallet locations are available.

-

In the finished products warehouse, three transition stackers are used to store and retrieve lithium batteries. 31, 296 pallet locations are provided.

Project Outcome

The lithium battery can be storage in the high temperature warehouse of 50 degrees Celsius with the stacker which can resist high temperature.

Polyurethane coated rubber wheel and H-section steel/aluminum alloy stacker track meet the environmental cleanliness requirements of lithium battery production, such as dust and burr free.

Stacker equipped with fire extinguisher and armor device to meet the requirements of fire and explosion.

The WMS/WCS system can achieve the whole process automatically and unmanned, and record product information throughout the process to realize the information can be traced at any time, helping to improve the consistency of battery products.

Help clients create ultimately efficient supply chain system with intelligent product,systematic solution, continuously maximizing commercial value