E Class | What Is ABC Classification and How Can You Use It in Inventory Management?

Aug 30,2023

Summary

In the field of logistics, efficient inventory management is one of the keys to enterprise success. As a common inventory management method, ABC classification has been widely used in the logistics industry for its simple, efficient and practical characteristics.

Welcome to our E Class series article everyone! In the field of logistics, efficient inventory management is one of the keys to enterprise success. As a common inventory management method, ABC classification has been widely used in the logistics industry for its simple, efficient and practical characteristics. This article will give you an in-depth understanding of the meaning, origin, practical significance of ABC classification, and its application in warehousing logistics management.

What is ABC classification?

ABC classification, also known as ABC analysis, is a technique used to manage inventory and optimize supply chain.

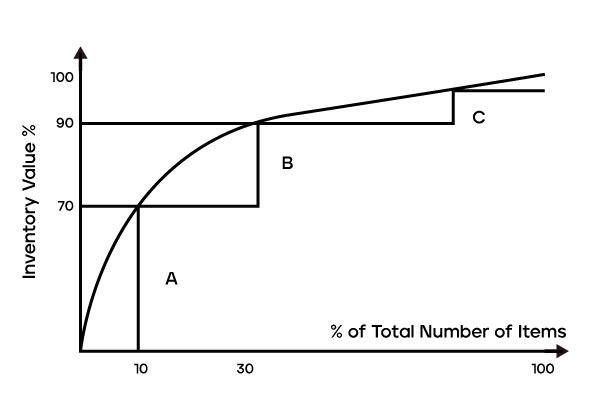

ABC classification classifies inventory materials into three ABC categories. Category A materials have the highest priority and inventory value, Category B materials have lower inventory value and Category C materials have the lowest value. ABC classification helps enterprises more efficiently manage various materials, control inventory costs, reduce the risk of material shortage, and better meet the production and delivery needs.

The origin of ABC classification

ABC classification is based on economist Vilfredo Pareto's 80/20 rule. It states that 80% of outputs are caused by 20% of the inputs. In the field of logistics, the Pareto principle is applied to inventory management, where a small number of materials have a significant impact on inventory costs and supply chain efficiency.

Advantages of ABC classification

ABC classification aims to allocate resources properly in order to better manage inventory and supply chain. Specifically, its benefits are as follows.

1. Prioritize the high-value materials: category A materials typically account for most of the inventory value, but it is the smallest category. By focusing on category A materials, enterprises can ensure that the supply and inventory management of high-value materials are prioritized to avoid production disruptions or customer satisfaction decreasing.

2. Save costs: enterprises can better control inventory costs in terms of category A materials. For category B and C materials, relatively flexible inventory management methods can be used to reduce operating costs.

3. Improve inventory turnover: inventory turnover will increase as category A materials usually require more frequent procurement and inventory management. It helps to reduce products overstocking, free up funds and reduce overdue materials.

4. Forecast demand: by classifying different categories of materials, enterprises can more accurately predict the demand for different materials, to better plan production and supply, and reduce inventory fluctuations.

ABC classification in the field of logistics

ABC classification is widely and deeply applied in the field of logistics. Taking a logistics center as an example, enterprises can use different warehousing strategies for different types of materials. For category A materials, fixed point inventory can be taken to ensure that they are always available. For category B materials, regular inventory strategy can be used to ensure the accuracy of inventory. For category C materials, you can use order management to avoid overstocking.

At the same time, logistics enterprises can also adjust the supply chain strategy with ABC classification. For category A materials, enterprises can establish a close cooperation relationship to ensure stable supply. For category B and C materials, you can find more flexible supply options to reduce costs.

In conclusion, with ABC classification, enterprises can better manage inventory, optimize supply chains, increase efficiency and ensure customer satisfaction. In the field of logistics, the application of ABC classification not only helps enterprises improve the level of inventory management, but provides strong support for their business development. Let us hope that it can be more widely and efficiently applied in the constantly developing era of intelligent logistics.

For more about logistics, stay tuned for the next E Class series article!