Enotek Group Delivered a Speech at the 9th Global Supply Chain Conference of GLSC2023

Sep 14,2023

Summary

Recently, the 9th Global Supply Chain Conference (GLSC2023) was held in Shanghai, China. At the Automotive and New Energy Summit, Mr. Wayne Xu, CTO of Enotek Group, delivered a keynote speech entitled "Future Moves Now — Smart Logistics Helps Boost the Automotive and New Energy Industries", and put forward a series of solutions to the logistics challenges in the rapid development of the automotive and new energy industries.

Recently, the 9th Global Supply Chain Conference (GLSC2023) was held in Shanghai, China. At the Automotive and New Energy Summit, Mr. Wayne Xu, CTO of Enotek Group, delivered a keynote speech entitled "Future Moves Now — Smart Logistics Helps Boost the Automotive and New Energy Industries", and put forward a series of solutions to the logistics challenges in the rapid development of the automotive and new energy industries.

Smart logistics for the automotive industry

According to the data released by China Federation of Logistics and Purchasing, in the first half of 2023, China's logistics volume for automotive manufacturing maintained a higher growth level of more than 20%. Mr. Wayne Xu said that along with the rapid development of the automotive industry, the demand for automotive manufacturing logistics is also growing. Meanwhile, many enterprises are also facing various logistics management pain points like high costs, rapid changes, lack of traceability, for which Enotek Group has given specific solutions.

Increase automation: reduce manual workers by adding automated equipment, to improve overall logistics efficiency.

Integrate hardware with software: integrate software systems with hardware equipment to realize intelligent logistics management while maintaining flexibility to adapt to rapidly changing needs.

WMS/WCS: use WMS (Warehouse Management System) and WCS (Warehouse Control System) technologies to realize accurate traceability and management of the logistics process.

Digital production system: achieve digital monitoring and management of the production process by digital technology, to improve production efficiency.

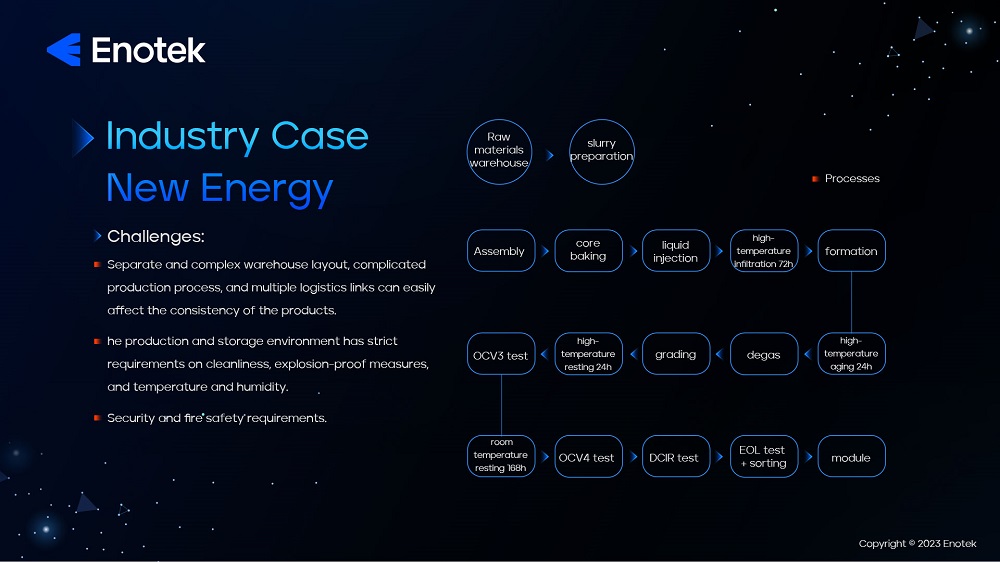

Smart logistics for new energy

According to the data released by the China Federation of Logistics and Purchasing, the growth rate of China's logistics volume in the new energy field also exceeded 20% in the first half of 2023. In terms of the pain points of logistics in the new energy field like harsh environment, flammable and explosive conditions, and fire hazards, Eontek Group has developed new energy high-temperature resistant stacker cranes with automatic fire extinguisher and explosion-proof device. Enotek new energy stackers can run safely and stably under harsh environment, flammable and explosive conditions, providing a strong guarantee for the intelligent logistics of new energy industry.

Typical case studies

In this speech, Mr. Wayne Xu also shared the typical project cases in the automotive industry and the new energy field respectively. In a customized intelligent logistics project for a leading enterprise in the new energy industry, Enotek Group fully considered the special nature of materials, set up explosion-proof measures for the warehouse, and divided the warehouse into five storage areas, including high-temperature warehouse, formation warehouse, grading warehouse, normal temperature static warehouse and finished products warehouse, to realize the scientific classification and management of different types of materials.

In the project, Enotek Group has applied 17 stacker cranes and set 18,032 storage spaces. Through innovative product design, the explosion-proof requirements of the stackers' loading platforms have been realized to improve the safety of the whole storage area during operation. At the same time, automation systems have been adopted to realize the functions of automatic inbound, accurate outbound picking and returning. With the reduction in manual workers, the efficiency and accuracy have been greatly improved.

With the development of intelligent technology, Enotek Group will continue to be committed to providing the industry with more advanced and efficient logistics solutions, helping enterprises develop and move towards a greener and smarter future.