The rise of intelligent logistics system integration in China

Sep 02,2022

Summary

"Today I heard two investments, one invested in intelligent logistics, the other also invested in intelligent logistics. In the past few years, the smart logistics industry boom, can be seen from this phrase.

"Today I heard two investments, one invested in intelligent logistics, the other also invested in intelligent logistics.

In the past few years, the smart logistics industry boom, can be seen from this phrase.

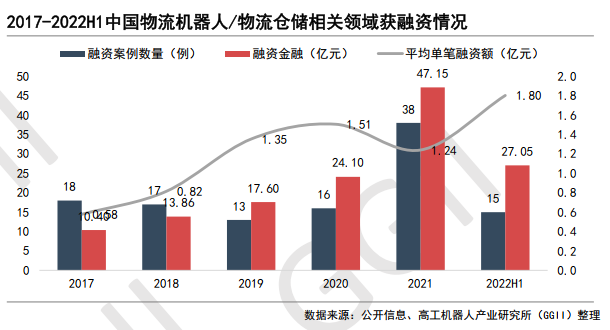

High-tech Robot Industry Research Institute (GGII) statistics from 2017 to 2022H1 China logistics robot/logistics warehousing related fields of financing, in 2017 still hovering around 1 billion yuan, in 2021 rushed to 4.715 billion yuan. In just four years, the amount raised has nearly quadrupled. In the first half of this year, the amount of financing reached 2.7 billion yuan.

The stable development of intelligent logistics industry cannot be separated from the contribution of system integration manufacturers. Unfortunately, although the development has been years, but compared with Dematech and other international giants, domestic intelligent logistics system integration enterprises are still weak in size.

Dematic officially entered China in 1996 and built a factory in Suzhou in 2006. After years of hard work, Dematic has landed more than 1000 integrated projects in China. So far, Dematic's annual revenue has reached nearly 30 billion yuan ($4.299 billion in 2021), while only a handful of domestic manufacturers can reach 2 billion yuan in revenue.

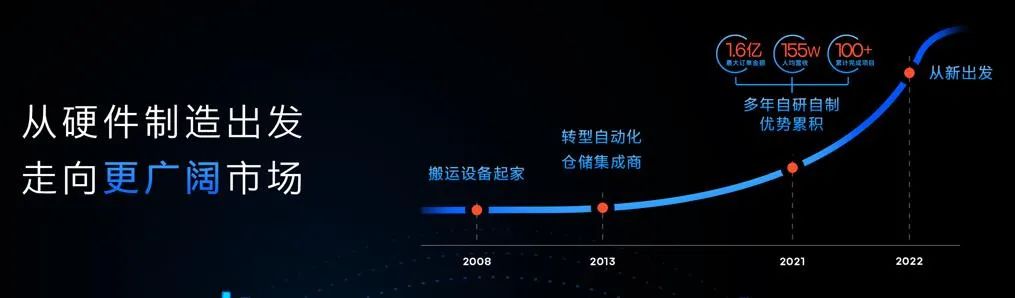

Twelve years after Dematic entered China, a Chinese intelligent logistics system integration enterprise aiming to rival Dematic was established in Jiaxing. The enterprise named EOS, is the predecessor of Enotek Group, founded at the beginning of the main light small forklift machinery manufacturing. In 2013, five years after its establishment, Enotek Group officially completed its transformation into a solution provider.

Enotek Group is committed to becoming an international standard solution company with its own core standard products, to achieve curve overtaking, and to become the vanguard force leading the rapid development of China's industrial intelligent logistics industry.

After 14 years of development, Enotek Group has become an innovation-driven full-link industrial intelligent logistics solution provider, able to provide overall logistics planning for new plant.

In terms of hardware, Anke technology self-developed stacker, pallet stacker horizontal running speed can reach 240m/min, material box stacker horizontal running speed can reach 360m/min, positioning accuracy in ±3mm, maximum height up to 40M, minimum temperature up to -30℃, maximum load 8000KG, Can adapt to the height and efficiency requirements of different customers.

Enotek AGV series products are equipped with self-developed AGV scheduling system. EA-T/G series AGVs adopt laser navigation technology, which can realize collaborative work of multiple devices and optimize task management. EA-B series AGVs can be customized for different users' needs.

In terms of software, Enotek Group self-developed WMS and WCS system, AGV scheduling system, digital twin system.

At the same time, according to the industry, the degree of intelligence, the specific business, Enotek Group can also provide customized system development services.

In terms of system, the core business of Enotek Group includes intelligent storage system, intelligent sorting system, intelligent handling system, intelligent sorting system, solutions covering chemical fiber, new energy, new materials, auto parts, paper, electronic appliances, food and beverage and many other industries.

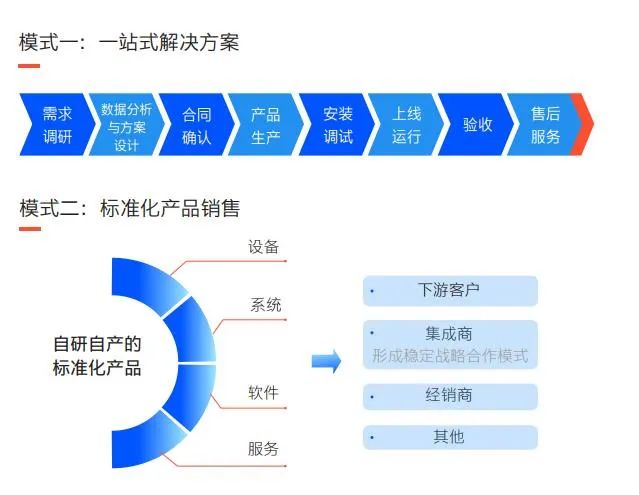

Up to now, Enotek Group has been able to provide customers with a full-link industrial intelligent logistics solution covering "equipment + software + system + platform service", covering intelligent warehousing of raw materials, raw material transportation, line logistics, finished product distribution and other links, and has landed more than 100 smart logistics projects.

In the past 14 years, Enotek Group is how to win the trust and recognition of customers step by step?

01 Strategy One dislocation cooperation & widening the track

Unlike Dematic, which focuses its business on apparel, consumer goods, food and beverage, general merchandise and other industries, Enotek Group has set its sights on previously uncultivated land -- chemical fiber, glass fiber and other industries.

Enotek Group selects chemical fiber and glass fiber industry in a misplaced way, and becomes the first echelon supplier of this industry, maintaining stickiness with leading customers such as Tongkun, China Jushi, and Xinfengming Group.

Chemical fiber products are large in size, difficult to carry and easy to be damaged, which requires high technical requirements for warehousing and logistics integration. Enotek Group formally entered into the chemical fiber industry by undertaking the project of Xingfengming Group. In this project, Enotek Group provided a total of 18 stackers, established 20,000 + storage space for Xingfengming Zhongyi chemical fiber, and equipped with independently developed WMS and WCS system. After the completion of the project, the warehouse has become one of the most efficient warehouses in Xinfengming Group.

Xinfengming Zhongyi Chemical fiber Project

Chemical fiber giant Tongkun is also one of Enotek's customers. Tongkun Shares put forward logistics solutions to solve the irregular warehouse topography and meet the import and shipment scheduling requirements of "warehousing by SKUs, warehousing by orders" and "warehousing by preferred department suppliers". Enotek Group chose to use a number of stackers with a height of 25.5 meters, and successfully established more than 20,000 storage locations in the reservoir area, realizing high utilization of space and maximizing logistics efficiency. The backtracking function of WMS software maximizes the efficiency of the equipment in this project and reduces the adverse impact caused by the complex site.

This project opens the door for long-term cooperation between Enotek Group and Tongkun. In 2020 alone, Enotek Group signed a 100 million cooperation order with Tongkun Shares.

In the finished product storage solution of a listed company in the glass fiber industry, Enotek Group provides 18 sets of double column stacker, 26 pallet loading and unloading platforms, 1 set of pallet chain conveyor and 1 set of pallet roller conveyor, and 1 set of WCS and WMS software systems, which can reduce the system's warehousing efficiency to 100 torches/hour and warehousing efficiency to 50 torches/hour, reducing the error rate.

Enotek Group also has accumulated experience in automobile and new energy, environmental protection new materials, paper, electrical, medicine, furniture and other industries, and has gained quality customers such as Luxshare Precision Industry, Jiangsu Jiatong Energy, :Zhejiang Dibay Electric and so on.

Dislocation cooperation, widening the racetrack strategy to Enotek Group brings huge advantages. It is understood that the order amount of Enotek Group in 2020 is about 400 million yuan, of which the largest order amount is 160 million yuan; In 2021, its order volume reached 560 million yuan; Enotek Group is expected to reach 800 million yuan of orders this year.

02 Strategy two study extremely perfect & seize the demand

Based on customer needs, Enotek Group insists on promoting technological improvement, and is one of the first local logistics technology enterprises to promote digital twin, machine vision, AI algorithm and other cutting-edge technologies. Especially in the promotion and application of digital twin technology, Dematic and the standard does not fall behind.

Digital twinning, as it's called, is a technique that digitally copies physical assets and updates them in real time to match the real world.

Dematic uses digital twin technology to build warehouse simulation software to help improve layout and workflow, intuitively understand changes in the production line, thereby identifying problems in advance and reducing production risks, enabling customers to have an immersive digital warehouse experience and help predict the future direction of the production line.

The prototype of Enotek's digital twin logistics system is a 3D monitoring technology, which began to be used in the smart logistics project of Zhejiang Dinmei Intelligent Decoration Co., Ltd in 2018. With the further development of hardware and software technologies such as 5G communication and virtual simulation, Enotek's 3D monitoring technology has gradually developed into a technology with a more scientific and technological name -- digital twin.

In 2020, Enotek Group deployed its first digital twin system. In 2021, China Stonehenge officially laid the foundation stone for the glass fiber pool kiln drawing production line with an annual output of 120,000 tons in Egypt. Enotek Group applied the new version of digital twin system after iterative upgrading in the project.

The new version of digital twin technology can provide more refined and visual data, create the whole process of visual management, better optimize the production process and decision aid:

-- Have a deep understanding of equipment mechanism: started from equipment manufacturing and have the ability to develop and make their own, more familiar with the operation logic of equipment. Compared with simply accessing third-party data to do digital twinning, richer and deeper device data types and data contents can be obtained.

-- Rich industrial experience: in-depth understanding of Chinese manufacturing process and demand pain points.

-- Equipped with intelligent maintenance system: it can detect the condition of hardware equipment and provide early warning.

-- Data refinement: Enotek provides richer device data access for digital twin systems due to its self-developed products, enabling more accurate and time-free visualization.

-- Data analysis ability: can assist customers to make decisions and effectively optimize the warehouse structure.

In Enotek Group 's blueprint, the future of manufacturing belongs to "black light factories". Using digital twin technology, Enotek Group can accurately restore logistics management one by one, effectively help customers optimize decisions, improve management efficiency. Using machine vision and AI algorithms, in-plant logistics can better coordinate with production and supply.

03 Policy Three Service Guarantee & Late maintenance

In the eyes of some people, integrators only have integration capabilities, but no core hardware products. Enotek Group proves with practice that in order to realize intelligent logistics, it must be supported and guaranteed by core technologies. "From the long-term development consideration of the enterprise itself, 'delivery' is only the end of the surface, and the later 'service' is another kind of beginning."

Enotek Group began to develop software in 2015. The service team has an international perspective, has been deeply engaged in the industry for several years, has the integration ability and delivery ability of the whole industrial chain, and covers the whole chain services such as independent research and development, scheme design, large-scale production, sales and installation.

Both Dematic and Enotek Group can provide technical training services, and both can tailor training programs to actual needs. But in the after-sales phase, Enotek Group to provide services beyond.

After the end customer production line is in full operation, if there is a problem, every extra second can cause more losses. Enotek Group can provide 7X24 hours Shanghai office expert hotline support; 7X24 hours for VPN remote login WMS hotline support; Telephone response and remedial action within 1 hour.

Most importantly, if the remote solution is not available within 8 hours, Enotek Group uses a 24-hour arrival service. That's something Dematic has struggled to achieve.

Enotek Group can provide inspection services, including the inspection of storage equipment, that is, the sub-system inspection and correction, maintenance, training; WMS system inspection, that is, WMS inspection, health report and recommendation, and training.

Enotek Group can also provide on-site services, short-term on-site, accompany customers familiar with the use of the system; Long-term on-site to assist customers in long-term operation system update and optimization.

Customers can also independently purchase renewal services, including system operation support, mechanical and electrical support, system expansion and upgrade, spare parts supply, etc.

04 Strategy Four transformation development & intelligent manufacturing upgrade

Sunken boat side, thousands of sails race; Before the sick tree, all trees meet spring. Innovation, research and development, transformation and upgrading are important means for enterprises to maintain vitality and competitiveness.

In 1959, Dematic developed a stacker to enhance its competitiveness; In 2008, Enotek Group started to develop its own stacker and made it one of its core products.

In 1995, in order to better connect with end customers, Dematic chose to transform into an internal logistics integrator. In 2013, facing the automation demand of customers, Enotek Group transformed into a provider of intelligent warehousing solutions.

With the expansion of the company and its transformation to an intelligent and platform-based direction, Enotek Group chose to upgrade its brand in early 2022, even though the original brand Eoslift is well known in the logistics industry.

According to the interpretation of Jiang Yuejun, chairman and CEO of Enotek Group: Eoslift refers to figurative products, and "lift" refers to forklift handling equipment. The new brand, Enotek, sounds like the English word "Tech" for "tek" and "technology", indicating the company's determination to take the lead in technology.

China's intelligent logistics industry is developing at an astonishing speed. At present, the automation level and complexity of some projects in China can be compared with some projects in Europe and the United States. In the next 5 to 10 years, the domestic market for logistics automation is still urgent demand.

Facing the changing times, Enotek Group chooses to ride the wind, open intelligent logistics upgrade, put forward the "E mode" :

E Customized. Both technology and cost-effective customized innovation, to meet the personalized needs of "thousands of fields and thousands of faces".

E adjustment. Through the flexible number intelligence system, enterprises are more flexible in the face of order volume changes and business expansion.

E Management. Through digital twin, AI algorithm and other digital intelligence technology, reduce the difficulty of manufacturing logistics management.

Given the late start and small and scattered market, it is indeed difficult for domestic manufacturers to compete with international giants in a short time just from the perspective of size. I am glad to see that a group of Chinese local intelligent logistics system integration enterprises represented by Enotek Group can devote themselves to technology research and development, improve business strength, make in-depth exchanges with partners in the industrial chain, and actively connect with end customers. Looking back on the past, the road is bumpy, we have suffered more; Looking forward to the future, believe that the bright future.

Disclaimer: The content of this article is reprinted from Gaogong mobile robot, the content does not represent the position of the platform, only for learning and communication. We maintain a neutral attitude towards the contents and opinions stated herein and do not provide any warranty as to their accuracy, reasonableness or completeness. We do not assume any liability for any loss resulting from inaccurate, unreasonable or omissions of information.