Open the door of the "meta-universe" with digital twin technology to accelerate the development of intelligent logistics industry

Sep 06,2022

Summary

The 2022 World Artificial Intelligence Conference has been successfully concluded at the Shanghai World Expo Center on September 3. The theme of this year's conference is "the Creation of a World without Boundaries". The core technologies of the meta-universe, including virtual original, digital twinned and spatial computing, support the keynote interpretation of the conference from the evolution of AI itself to the meta-universe supported by AI. It shows the "core new technology, new industrial track, new future scene and new governance issues" under the background of the integration of artificial intelligence and meta-universe, presenti

The 2022 World Artificial Intelligence Conference has been successfully concluded at the Shanghai World Expo Center on September 3. The theme of this year's conference is "the Creation of a World without Boundaries". The core technologies of the meta-universe, including virtual original, digital twinned and spatial computing, support the keynote interpretation of the conference from the evolution of AI itself to the meta-universe supported by AI. It shows the "core new technology, new industrial track, new future scene and new governance issues" under the background of the integration of artificial intelligence and meta-universe, presenting a new picture of a better and more vivid future.

In recent years, the concept of "metaverse" has been completely out of the limelight. So what exactly is a metaverse? What does it have to do with "digital twinning"?

What is a metaverse?

On the Internet, the new concept of metacomverse is explained as a virtual world that is linked and created by means of science and technology, maps and interacts with the real world, and a digital living space with a new social system. From the perspective of time and space, the meta-universe is a virtual digital world in space dimension and a real digital world in time dimension. From the perspective of authenticity, there are both digital copies of the real world and creations of the virtual world in the metaverse. From the perspective of independence, the meta-universe is a parallel space which is closely connected with the external real world and highly independent. From the perspective of connectivity, the metaverse is a virtual reality system with a continuous, extensive coverage that includes the network, hardware terminals and users.

What is the relationship between the metacomes and digital twinism?

Digital twinning actually includes three aspects: one is the real goods in the real world, the other is the virtual goods in the virtual world, and the third is the data information exchange between the real world and the virtual world. The world in the meta-universe also includes three aspects: the first is the real world, the second is the virtual world, and the third is the data and information exchange between the real world and the virtual world.

Digital twinned networks may form the core foundation of the metaverse. Relevant professionals point out that with the development of technology, digital twin application will expand the connected objects of the Internet of Things into physical and virtual twins, and integrate the physical object space with the virtual object space to become a virtual and real mixed space. The Internet of Things will develop into a new generation of digital twin network, which may become the third generation of Internet applications, and even become the core foundation of the metauniverse.

Metauniverse is actually the further development of digital twin technology, is the integration of virtual reality technology of digital twin technology, when the application of digital twin technology from the industrial field extended to all aspects of people's production and life, the prototype of the metauniverse was formed.

Digital Twin System -- the meta-universe of intelligent logistics

Throughout the future scenario conception under the concept of metauniverse, various advanced technologies collide and interact with each other, resulting in the application of metauniverse related technologies in the logistics system. In fact, the logistics industry has never stopped upgrading and iterating in the digital field, gradually moving from digitalization to digitalization, and intelligent logistics is born along with the trend.

Digital twinning is the core technology of logistics industry under the concept of meta-universe. It is a multi-disciplinary, multi-physical quantity, multi-scale and multi-probability simulation process that makes full use of physical model, sensor update, operation history and other data, and completes mapping in virtual space, so as to reflect the full life cycle management of corresponding physical equipment. In the industrial intelligent logistics industry, digital twin technology plays an important role. Through virtual logistics equipment in the real world, it can rely on big data and machine learning to analyze massive logistics data, optimize the storage structure of the warehouse, optimize the operation efficiency of the equipment, and assist decision-making and maintenance, so as to release great potential for enterprises.

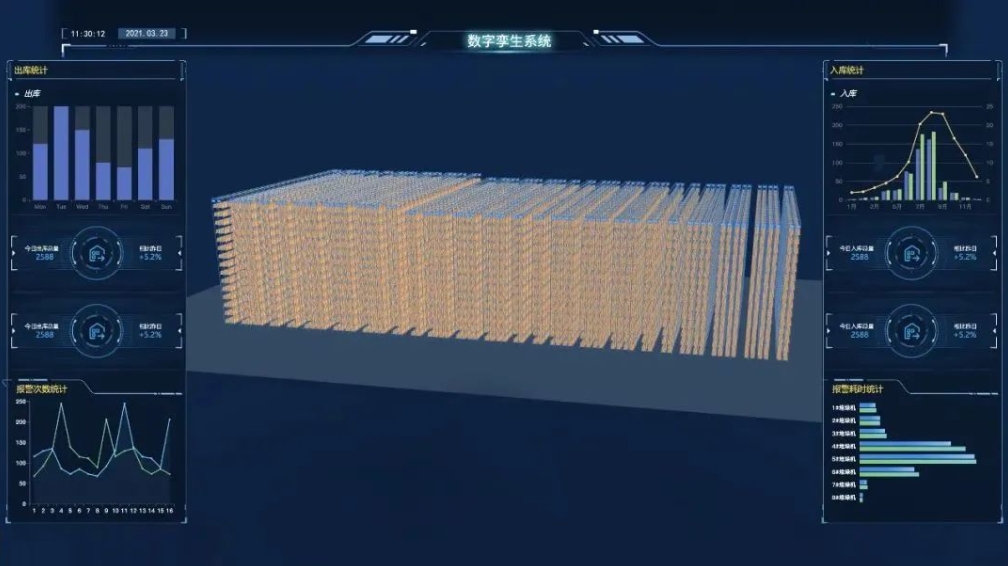

Enotek Digital twin system

Enotek digital twin system is a 3D real-time monitoring storage environment, and can be viewed in the browser window to reflect the real-time storage monitoring system, a more intuitive reflection of the real-time storage situation. The main functions include 3D simulation display of real scene of stereo library, real-time physical location, status data, fault monitoring of stereo library equipment, remote camera monitoring, etc. The system can make the warehouse management personnel more quickly and intuitively obtain the implementation of the running track of equipment, fault, etc., which plays a key problem for the management personnel to obtain the problem in the first time.

Advantages:

Rich visualization: high visualization degree, fine granularity, high degree of twinning, equipment status and cargo location information clearly visible more intelligent devices and sensing devices access, such as temperature and humidity and other more data display with WMS/WCS system and AGV dispatching system to achieve data connection, real-time view of AGV equipment real-time operating data.

Convenient operation: diversified customized reports, configurable functional modules, can achieve rapid deployment with duplex communication capability, seamless connection with PLC equipment, comprehensive update of the display interface, friendly operation interface to achieve multi-scene and multi-area display, multi-area smooth transformation.

Intelligent: carry out big data analysis on inventory and incoming and outgoing data, optimize inventory storage structure, improve the granularity of inventory management and integrate machine learning function, which can analyze and predict equipment failures and carry out equipment maintenance in advance.

Exploration and application of digital twin technology in intelligent logistics field

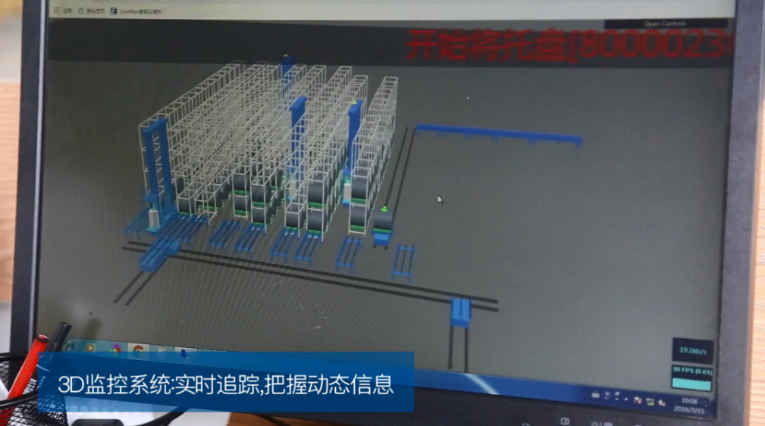

In 2018, in the intelligent logistics project of Zhejiang Dinmei Intelligent Decoration Co., Ltd., Enotek's equipment monitoring innovation adopted 3D mode, which realized the equipment monitoring in the reservoir area for customers. Help enterprises to check equipment information at any time, understand the working situation of the reservoir area, monitor the running status of the equipment, and discover equipment faults in time.

At first, 3D monitoring technology was crude. Although the 3D three-dimensional monitoring in the reservoir area has been realized, it is not precise enough in the scene and equipment display. The tiny movements of many devices cannot be displayed, and the massive data cannot be processed.

With the further development of hardware and software technologies such as 5G communication and virtual simulation, 3D monitoring technology has gradually developed into a technology with a more scientific name -- digital twin. Enotek's 3D monitoring system is also iteratively upgraded to Enotek digital twin system after the implementation and application of multiple projects.

In 2020, the company deployed its first digital twin system for a customer in the glass fiber industry, which can visually display the equipment and cargo locations in the reservoir area in three dimensions, reflect the working status in real time and accurately, provide accurate reports, and provide decision-making basis for managers.

From 3D monitoring to digital twinning, Enotek system has achieved the following upgrades:

1. The display interface is updated comprehensively and the operation is more friendly

2. Higher degree of visualization, finer granularity, higher degree of twinning, equipment status and cargo location information clearly visible

3. Multi-scene and multi-region display, multi-region smooth transformation,

4. Make data connection with WMS/WCS system and AGV dispatching system, and view AGV device operation report in real time

5. Access of more intelligent devices and sensing devices can realize more data display, such as temperature and humidity

6. More diversified customized reports with configurable function modules can realize rapid deployment

On October 8, 2021, a glass fiber industry customer officially laid the foundation for a glass fiber pool kiln drawing production line with an annual output of 120,000 tons in Egypt. Enotek Group will build an automated stereo library and intelligent production line for it, and will play an important role in the application project of the new version of digital twin system after iterative upgrading.

Enotek's new version of digital twin technology can provide more refined and visual data, create the whole process of visual management, better help customers to do production process optimization and decision aid:

Have a deep understanding of the mechanism of the equipment: started from the equipment manufacturing and have the ability of self-research, more familiar with the operation logic of the equipment. Compared with simply accessing third-party data to do digital twinning, richer and deeper device data types and data contents can be obtained.

Rich industrial experience: in-depth understanding of Chinese manufacturing process and demand pain points.

Equipped with intelligent maintenance system: it can detect the condition of hardware equipment and provide early warning.

Data refinement: Enotek Group provides richer device data access for digital twin systems due to its self-developed products, enabling more accurate and time-free visualization.

Data analysis ability: can assist customers to make decisions, effectively realize the optimization of warehouse structure.

In the future, logistics may be able to realize the passage of data and goods between the physical world and the digital world. With the rapid development of the Internet and digitalization, it seems foreseeable and expected that human beings will build the meta-universe into the ultimate scientific and technological world.